With the demand for consumer products, witnessed by a sharp increase in recent years in the dry mix industry, an efficient and robust packaging solution is the main need. One of the most important pillars of the packaging domain is the implementation of high-speed and efficient packaging equipment.

Traditionally, the industry uses Open mouth bagging machines where an operator has to manually insert the bag (HDPE with PE liner) on a nozzle of the machine and clamp it with the help of a footswitch or sensor. Filled bags are then directed to a stitching machine manually. Filling machines are designed to provide an output of 5 bags/min, however, due to the manual operation, the average bagging rate is reduced to 2 or 2.5 bags/min. This process requires 2-3 persons resulting in an approximate cost of Rs.40/ton.

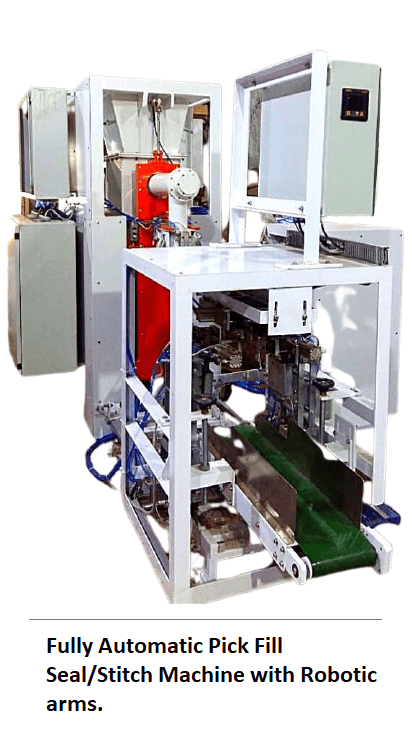

VT Corp has developed a robotic bag placer & bag dispenser which helps to automate this entire process. A bag is picked from the stacker & is placed in the nozzle of the machine with the help of a robotic bag placer. Filled bags are then dispensed by the robotic dispenser & sent directly to the stitching machine. This ensures the output of 5 bags/min with only 1 operation supervisor.

Hence this automation, considerably reduces the manpower, operational expenditure & time, resulting in increased production.

To further accelerate the process, we offer a fully automatic palletizing system, where packed bags can be robotically placed on the pallet using our automatic Palletizer. We will further update you on how to increase production in a well-timed & cost-effective manner, in our next article.