VT CORP product range consists of Pulse Jet Bag Filters in an online and offline type model, Insertable type units.

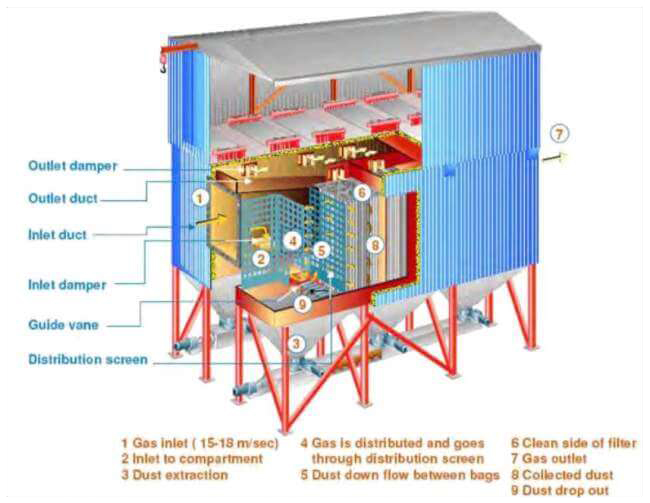

Pulse jet Bag filters are the fabric based self-cleaning dry filtration system that removes particulate matter and dust from the surface of the internal by the sequentially controlled burst of the compressed air. According to the Application and process parameters these systems can either be selected in ONLINE and Modular construction-based OFFLINE cleaning mode.

VTC filter based systems can control particulate emission or product recovery in most of the industrial applications including broadly Boilers, various types of Furnaces, Kilns, Mills, and various material handling applications and more than 100 + applications.

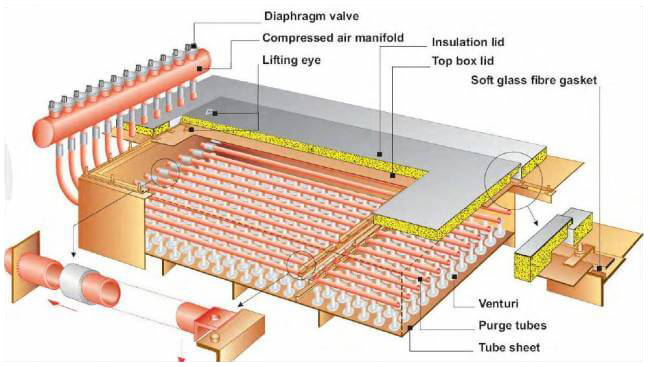

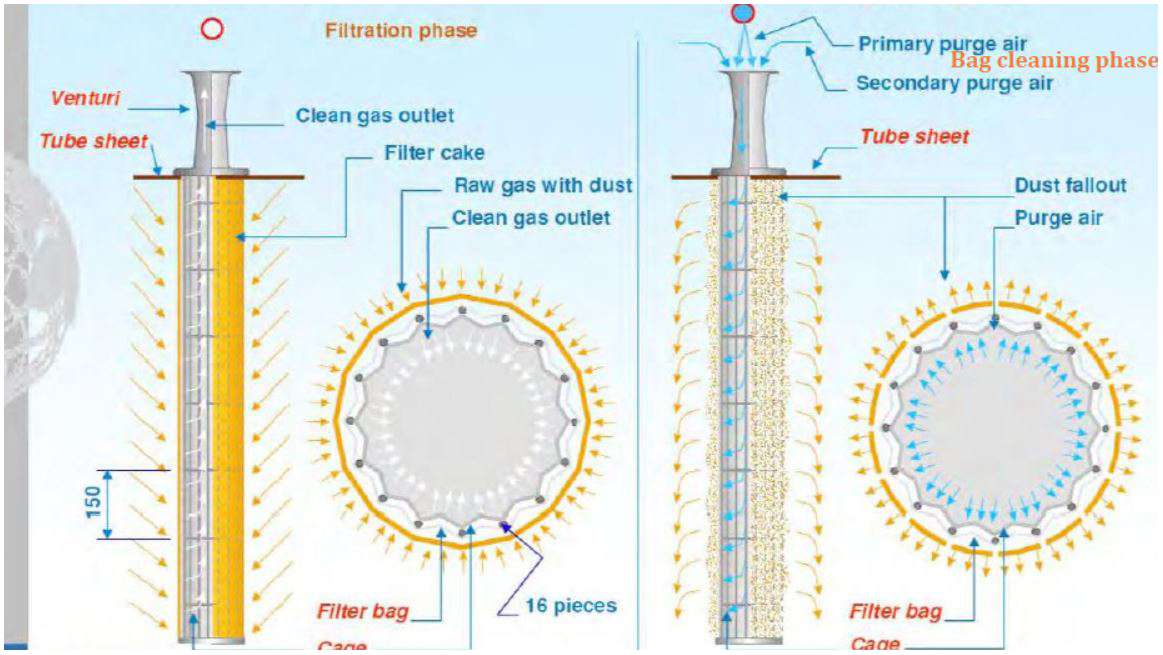

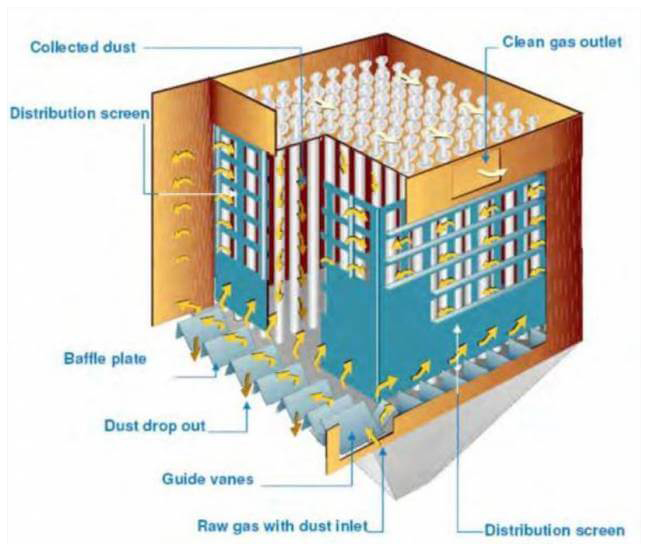

VT CORP Pulse Jet Fabric Filter contains an array of cylindrical filter bags suspended from a tube sheet separating the dirty and clean gas stream within a fabric filter compartment. Each bag has an internal wire cage supporting the filter bag preventing collapse of the filter media. Dust laden flue gas enters the filter inlet manifold through the process ductwork. Dust is collected on the outer surface of the filtration media allowing only clean gases to pass through and into the top section above the tube sheet and then on to the outlet ducting and stack. The dust is removed from the filter bags by pulses of compressed air. The cleaning is initiated by a differential pressure measurement when a predetermined level of resistance across the filter is obtained.

During cleaning the dust falls into the hoppers to be taken away via the dust discharge system. The dust collection phase and bag cleaning phase are represented by the following graphic. Bag cleaning is the result of disrupting the cake build up by flexing the membrane with a pulse of compressed air which aspirates cleaned process gases downward into the filter bag.

Long Bag life

Long Bag life Low differential pressure / operating pressure

Low differential pressure / operating pressure Low compressed air consumption

Low compressed air consumption Can be offered according to site conditions

Can be offered according to site conditions Low initial set up costs

Low initial set up costs Varied bag lengths from 1.0 Mtrs to above 10 Mtrs

Varied bag lengths from 1.0 Mtrs to above 10 Mtrs Solid state / microprocessor based sequential control system

Solid state / microprocessor based sequential control system Low maintenance as no internal moving parts

Low maintenance as no internal moving parts Can handle the various critical type of dust :

Can handle the various critical type of dust :Explosive / Non Explosives, Sticky, Corrosive, Hygroscopic, Abrasive, Coarse / Fine.

Non Ferrous: Aluminium, Stainless Steel, Copper, Zinc

Non Ferrous: Aluminium, Stainless Steel, Copper, Zinc Ferrous: Primary Steel, Secondary Steel, Foundry, Iron

Ferrous: Primary Steel, Secondary Steel, Foundry, Iron Power Generation

Power Generation Cement

Cement Fertilizers

Fertilizers Various other application

Various other application